We carry out all our own sample preparation to ensure high quality data collection. To protect our highly sensitive equipment we regret that we are unable to accept samples that have been prepared elsewhere.

Sample preparation is included in the quoted price for all our QEMSCAN and SEM services.

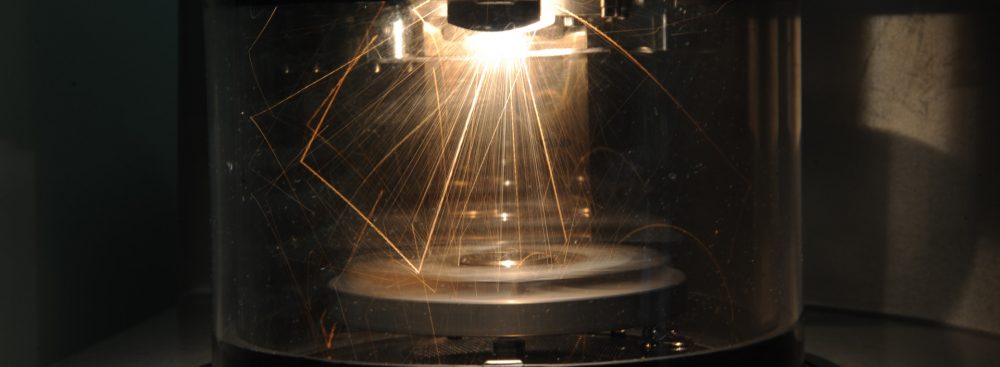

QEMSCAN is an acronym for Quantitative Evaluation of Materials by Scanning Electron Microscopy. Technically superior to other analytical tools it can process large volumes of samples in a short space of time. This helps you make more informed business decisions during the investment, exploration and production stages of projects.

QEMSCAN is an acronym for Quantitative Evaluation of Materials by Scanning Electron Microscopy. Technically superior to other analytical tools it can process large volumes of samples in a short space of time. This helps you make more informed business decisions during the investment, exploration and production stages of projects.